Location of leaks in cooling and air conditioning systems – SelectH2

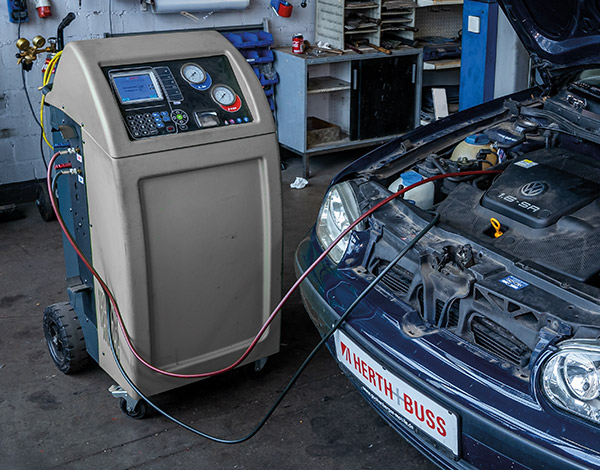

Location of leaks with our SelectH2 – The benefits

Our SelectH2 family has been successfully established on the market. With this innovative technology, we offer garages a method of leak detection in passenger car and commercial vehicle A/C systems that saves time and money while protecting the environment. Once the A/C system has been filled with forming gas, vibration leaks that are difficult to detect can be identified with variable adjustment of the pressure. The location of leaks using forming gas, which is 95 percent nitrogen and 5 percent hydrogen, is particularly efficient as even the smallest leaks can be found in leaking A/C systems.

Diagnosing faulty vaporisers

Environmentally friendly

Low-cost procurement of forming gas

Highly sensitive sensors

No misdiagnosis due to oil and gas vapours

Non-toxic

Made in Germany

For air-conditioning systems with R134a and HFO-1234yf

SelectH2 – The best device for detecting leaks in A/C systems

The SelectH2 selective gas detector is equipped with two gas sensors, which act like an artificial nose and only respond to hydrogen. Gas and oil vapours do not have a negative impact on the measurement result, so there is no longer any obstacle to effective and precise leak detection on your car or air conditioning system. This is the key difference compared with conventional detection units, which respond to the refrigerant R134a.

SelectH2 Types

|

|

|

|

|

| SelectH2 | SelectH2 | SelectH2Slim | SelectH2mini | |

| Display | With illuminated LCD display, battery status indicator, LED display |

With illuminated LCD display, battery status indicator, LED display |

With illuminated LCD display, battery status indicator mit LED-Anzeige |

With illuminated LCD display, battery status indicator |

| Lenght gooseneck | 320 mm | 500 mm | 500 mm | 320 mm |

| Housing type | Aluminium housing | Aluminium housing | Aluminium housing | Synthetic material housing |

| Dual sensor GGS 1000 / GGS 6000 |

Broadband, H2-selective |

Broadband, H2-selective |

Broadband, H2-selective |

Broadband, H2-selective |

| W x H x D | 52 x 178 x 35 mm | 52 x 178 x 35 mm | 52 x 178 x 28 mm | 44 x 175 x 36 mm |

| With Acoustic alarm | ■ | ■ | ■ | ■ |

| With integrated work light | ■ | |||

| With suction pump | ■ | ■ | ■ | |

| With extra slim sensor pump |

■ | |||

| Automatic zero-point calibration in fresh air | ■ | ■ | ■ | ■ |

| Automatic sensor check with fault detection |

■ | ■ | ■ | ■ |

| Power supply |

||||

| Output voltage | 12 V |

12 V | 12 V | 9 V |

| Plug type | Round plug | Round plug | Round plug | Round plug |

| Diameter | 3,5 mm |

3,5 mm | 3,5 mm | 2,5 mm |

| Part number: | 95980002 | 95980024 |

95980025 |

95980019 |

SelectH2 Types

|

|

| SelectH2 | |

| Gauge | with illuminated LCD display, with battery state display, with LED display |

| Length gooseneck | 320 mm |

| Housing type | Aluminium housing |

| Double sensors GGS 1000 / GGS 6000 |

broad band H2-selective |

| W x H x D | 52 x 178 x 35 mm |

| With acoustic alarm | ■ |

| With integrated work light | |

| With suction pump | ■ |

| With extra slim sensor head | |

| Automatic zero-point calibration in fresh air | ■ |

| Automatic sensor check with error detection | ■ |

| Power supply |

|

| Output voltage | 12 V |

| Plug type | Round plug |

| Diameter | 3,5 mm |

| Part number | 95980002 |

| Comparison overview | |

|

|

| SelectH2 | |

| Gauge | with illuminated LCD display, with battery state display, with LED display |

| Length gooseneck | 500 mm |

| Housing type | Aluminium housing |

| Double sensors GGS 1000 / GGS 6000 |

broad band H2-selective |

| W x H x D | 52 x 178 x 35 mm |

| With acoustic alarm | ■ |

| With integrated work light | |

| With suction pump | ■ |

| With extra slim sensor head | |

| Automatic zero-point calibration in fresh air | ■ |

| Automatic sensor check with error detection | ■ |

| Power supply | |

| Output voltage | 12 V |

| Plug type | Round plug |

| Diameter | 3,5 mm |

| Part number | 95980024 |

| Comparison overview | |

|

|

| SelectH2Slim | |

| Gauge | with illuminated LCD display, with battery state display, with LED display |

| Length gooseneck | 500 mm |

| Housing type | Aluminium housing |

| Double sensors GGS 1000 / GGS 6000 |

broad band H2-selective |

| W x H x D | 52 x 178 x 28 mm |

| With acoustic alarm | ■ |

| With integrated work light | |

| With suction pump | ■ |

| With extra slim sensor head | ■ |

| Automatic zero-point calibration in fresh air | ■ |

| Automatic sensor check with error detection | ■ |

| Power supply | |

| Output voltage | 12 V |

| Plug type | Round plug |

| Diameter | 3,5 mm |

| Part number | 95980025 |

| Comparison overview | |

|

|

| SelectH2mini | |

| Gauge | with illuminated LCD display, with battery state display |

| Length gooseneck | 320 mm |

| Housing type | Synthetic material housing |

| Double sensors GGS 1000 / GGS 6000 |

broad band H2-selective |

| W x H x D | 44 x 175 x 36 mm |

| With acoustic alarm | ■ |

| With integrated work light | ■ |

| mit Ansaugpumpe | |

| With extra slim sensor head | |

| Automatic zero-point calibration in fresh air | ■ |

| Automatic sensor check with error detection | ■ |

| Power supply | |

| Output voltage | 9 V |

| Plug type | Round plug |

| Diameter | 2,5 mm |

| Part number | 95980019 |

| Comparison overview | |

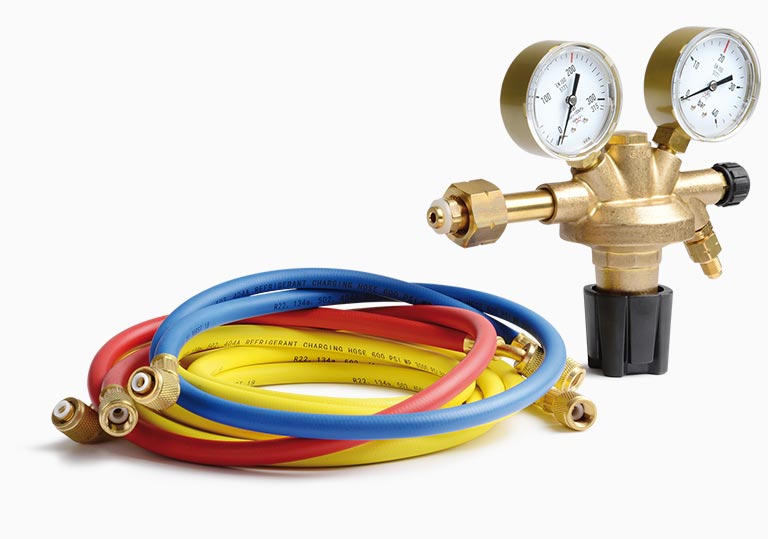

Filling A/C system with forming gas 95/5

Now fill the high-pressure side of the air-conditioning system with forming gas. The high and low-pressure side can be topped up simultaneously using the leak-location expansion set.

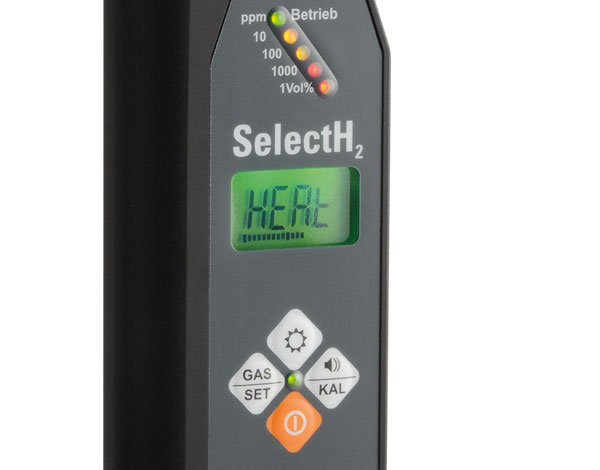

Heating up the device

The heat-up phase of the SelectH2 is signalled by the word "HEAT" and lasts approx. 50 seconds.

Repair and inspection

After repairing a leak, it is recommended carrying out another inspection using forming gas, followed by a functional check.

Filling with refrigerant and testing for leak-tightness

Fill the air-conditioning system with the appropriate refrigerant. Once you have filled up the A/C system, you should perform a functional test without fail.

Sight glass for refrigerant analysis

Our sight glass enables visual inspection of refrigerant or compressor oil and provides valuable information on their condition. Chips for example or other foreign bodies may have got into the system. You can also check whether compressor oil has become discoloured or contains water. Important information: The connections for R134a or R1234yf must be ordered separately.

- With integrated filter

- Easily disassembled for cleaning

Please contact us

*Required fields

Herth+Buss Fahrzeugteile GmbH & Co. KG

Dieselstraße 2-4

63150 Heusenstamm

Germany

+49 (0)6104-608-0

info@herthundbuss.com