JAKOPARTS –

ORIGINAL-QUALITY BRAKE PARTS

ALL YOU NEED FOR CHANGING BRAKES. EVERYTHING FROM A SINGLE SOURCE

Drum brakes, brake blocks, brake shoes, brake discs. Jakoparts – original brake parts of the highest quality.

The full range for Asian vehicles. Perfectly fitting. Certified. Guaranteed. Nowadays,

levels of effort and hours worked are optimised at modern workshops.

This is just one of the many customer requirements we have fulfilled for years with our practical, high-quality products and repair solutions.

Everything from a single source!

» REPLACING BRAKE DISCS AND PADS MADE EASY – FITTING PERFECTLY AND CERTIFIED

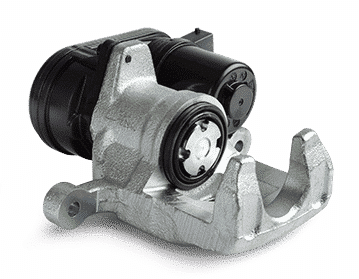

You can rely on brake discs and pads from our Jakoparts product range. Maximum safety and customer satisfaction are guaranteed thanks to continuous quality control of our ECE R90-certified brake discs and pads and our cooperation with TÜV Nord. All our brake discs are coated. This means they no longer need to be degreased. To save you time when replacing brake discs and to simplify the work operation. When replacing brake discs, the recommendation for running-in made in our installation instructions must be observed without fail.

- More than 700 references for Asian vehicles with a vehicle coverage of over 95 %

- Brake discs certified according to ECE-R90

- Coating offers protection against corrosion

- Perfect look for aluminium rims

- High temperature resistance

- Ease of handling thanks to low weight

- Maximum brake comfort through use of high-quality materials

- Regular material analyses conducted by an independent laboratory

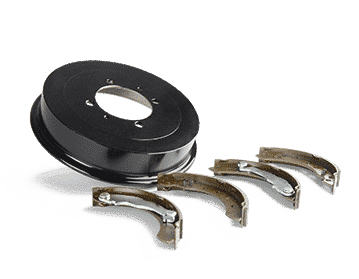

» DRUM BRAKE

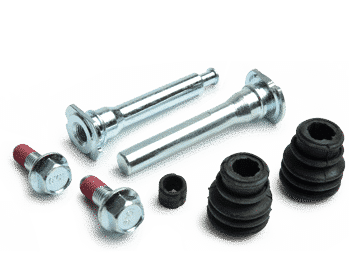

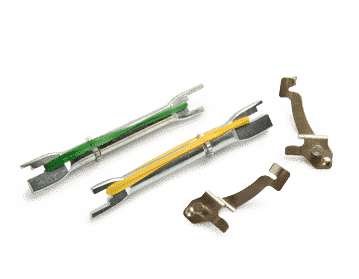

Drum brakes are becoming ever rarer in cars today. Drum brakes essentially consist of the brake drum, brake shoes, wheel cylinder, armature plate, adjusting mechanism, return springs and various fasteners. During braking, the wheel cylinder forces the fixed brake shoes apart and presses them onto the brake drum, which decelerates the wheel as a result. Drum brakes have decisive advantages over a disc-brake system. As it is a closed system, it is protected against environmental influences. It is also easier to incorporate a park brake into the system. The system can withstand longer downtimes, has a long service life and is cost-effective.

» BRAKE HYDRAULICS

In the brake hydraulics, the brake power is transferred via the brake fluid from the brake master cylinder to the individual wheel brake cylinders for the disc or drum brakes. When the engine is running, the pressure in the main brake cylinder created by pressing the brake pedal is augmented significantly by vacuum, so that greater deceleration can be achieved with a small amount of force on the pedal. As the pressure in the closed system is constant, the brake forces are automatically distributed to the wheel brakes evenly and synchronously. Hydraulic brakes have low friction losses when transferring forces and can be metered very easily.

Always fresh, little effort required: brake cylinders from the Jakoparts range for Asian vehicle models offer quality-controlled safety and reliability for both you and your customers.

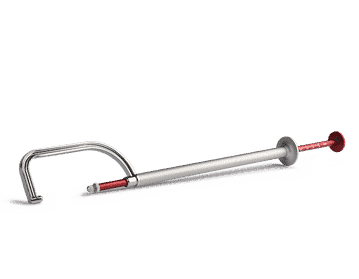

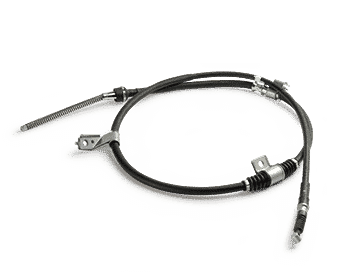

» PARK BRAKE

For a fast get-away: with complete solutions from the Jakoparts range, your retrofitting business for Asian vehicles won’t be held back by a pit stop. Punctuality guaranteed for all standard models.

The park brake performs the important function of providing extra security to a parking vehicle, or acting as an auxiliary brake in the event of the service brake failing. It works by permanently locking the vehicle’s wheels. It must be independent from the service brake and act upon all wheels on the rear axle. The park brake is also known as the cable brake, as it is operated as such using a hand or foot lever. Perfectly fitting replacement brakes: an example from practice

With over 18,500 vehicle-specific parts in our Jakoparts product range, we supply a comprehensive portfolio of products for Japanese and Korean vehicle models. Brake replacements are incredibly easy thanks to the assignment of perfectly fitting parts!

Perfectly fitting replacement brakes: an example from practice

With over 18,500 vehicle-specific parts in our Jakoparts product range, we supply a comprehensive portfolio of products for Japanese and Korean vehicle models. Brake replacements are incredibly easy thanks to the assignment of perfectly fitting parts!

How long is your braking distance?

The fact that the stopping distance during braking is made up of the reaction distance and the actual stopping distance is a classic of driving school knowledge. But how is the stopping distance calculated? Our video has the answer for you!

Advantages and disadvantages of all-season tyres

All-season tyres, often also known as all-weather tyres, are becoming increasingly popular. This is the conclusion drawn by the portal reifen.com. But what exactly are the differences and which tyre version is better suited to what type of people? The main differences are in the tyre profile and in the type of rubber used. All-season tyres can be driven all year round, provided they bear the Alpine symbol (3PMSF). This is prescribed for all-season tyres from year of production 2018. Only tyres with this snowflake symbol are actually approved for use as winter tyres. There is a transition period for M+S tyres produced until the end of 2017. These can still be used as winter tyres until 30.09. of this year.

What are the characteristics of a summer tyre?

Summer tyres are made of a slightly harder rubber and usually have a rougher profile, which means that they grip better in the rain, displace the water better and thus protect against aquaplaning. They also cope well with high temperatures and the rubber compound used guarantees safe driving on hot roads even at temperatures around 40 degrees Celsius. The braking power is good in both wet and dry conditions. It is important to know that the rubber compound of summer tyres hardens at temperatures below 7 degrees Celsius and thus loses its performance characteristics, especially on wet road surfaces. So you should never drive with summer tyres in winter.

And what about winter tyres?

The profile of winter tyres usually has many small fins and a larger tread depth. These ensure better grip in winter road conditions such as ice and snow, resulting in shorter braking distances. The rubber compound used is specially designed for cold temperatures, as it remains elastic even in frost and can thus adapt better to the surface structure of the road. Winter tyres are marked with the Alpine symbol (3PMSF mark).

All-season tyres - a compromise?

All-season tyres have a mixture of longitudinal grooves and fins and the rubber compound is a little softer and therefore more similar to the rubber compound of winter tyres. As a result, they combine the properties of summer and winter tyres. However, all-season tyres cannot match real winter tyres in extreme weather conditions. As with winter and summer tyres, a minimum tread depth of 1.6 millimetres is also required for all-season tyres, a minimum profile depth of 3 to 4 millimetres is recommended. It should also be noted that all-season tyres wear much faster, as they are driven all year round.

Conclusion

There is no clear recommendation. Ultimately, every driver has to decide which tyres are best suited for their requirements. For anyone who drives frequently in winter weather, perhaps even lives in the mountains and/or regularly go skiing, traditional winter tyres are the best option. All-season tyres can be a good compromise for anyone who prefers to leave the car at home in winter weather or only drives in the city and milder regions. After all, they combine the strengths of winter and summer tyres. Another advantage is that there is no need for the annoying tyre change and no storage space is required for the tyres that are currently not required. This saves time and money.

The new passenger car energy label

For many car dealerships and car dealers, it came very suddenly - the new passenger car energy label replacing the previous energy efficiency classes with the specification of a CO2 class. It came into force on 23 February without a transition period. Hardly feasible, as many car dealers note. The Central Association of the German Motor Vehicle Industry (ZDK) has also criticised this approach. If dealers fail to implement this change in time, they can expect warnings.

It came very suddenly, the new passenger car energy labelling regulation (Pkw-EnVKV). In concrete terms, this means: From 23 February 2024, all energy labels issued or published must meet the new requirements, there was no transition period. This was due to the Europe-wide switch to the WLTP test method (Worldwide harmonized Light vehicles Test Procedure).

So what's new?

In contrast to the previous energy label, which divided the vehicles into efficiency classes and only took consumption and emissions values into account, the new label divides the vehicles into CO2 classes and also contains additional information. This includes the amount of vehicle tax, the energy costs at a mileage of 15,000 kilometres per year and possible CO2 costs over the next ten years with an annual mileage of 15,000 kilometres.

One particular issue for dealers is that they have to state the expected CO2 costs over ten years. This involves a considerable amount of bureaucratic effort. They either have to request the data from the manufacturers or gather the details themselves in a different way. One saving grace is that labels created before 23/02/24 may still be used until 1 May this year. For advertising fonts and electronic, magnetic or visual storage media, the deadline is even 1 August this year.

What is the reason for the new passenger car energy label?

The new energy label is intended to provide consumers with better information regarding the energy efficiency of vehicle models. The vehicles are divided into seven CO2 efficiency classes, starting with the best energy efficiency class A, through to the worst class G. The aim is to reduce emissions from road traffic by encouraging consumers to buy cars with the lowest possible pollutant levels. There will be five energy labels in total, one for each type of fuel: Petrol, diesel, natural gas, pure electric vehicles and plug-in hybrids. The German government aims to improve acceptance with the introduction of the new energy label.

Glare in road traffic and why it poses a risk

Being dazzled when driving is not just unpleasant, but also dangerous. It is a common cause of accidents. A Europe-wide survey conducted by ADAC together with ten other automobile clubs, revealed that around 75 percent of drivers sometimes feel dazzled by bright lights from oncoming traffic.

How does glare affect drivers on the road?

Glare from the headlights and lights of other vehicles is not only a safety risk resulting in an increased risk of accidents, but also causes stress and discomfort for drivers. Many drivers feel impaired in the evenings in particular. Drivers complain that their visibility is restricted, especially in poor visibility conditions such as rain weather, snowfall or fog. The poorer visibility of objects is also listed as an issue. The survey also shows that it's not just older drivers who feel affected, but also many younger ones in the up to 35 age group. 21.8 percent of those surveyed even stated that they drive less in the dark overall.

What causes glare?

Drivers find it particularly disturbing when they are dazzled by the high beam of oncoming vehicles. However, the low beams are also regularly perceived as dazzling. The rear fog light is only perceived as disturbing by around a quarter of those surveyed. Daytime running lights, on the other hand, are not highlighted as having a major glare effect. However, the lighting on bicycles is increasingly being mentioned as a factor. This effect is also reinforced in the dark, and in specific ambient and weather conditions. Another factor is the increase in modern LED and laser light systems, as they can cause stronger glare.

What can drivers do to protect themselves against glare?

Most drivers react intuitively to glare. They often squint, look away briefly or, in the worst case, even close their eyes for a moment. This is a major problem for road safety. But what can drivers do to protect themselves and others from glare? The ADAC recommends the following measures: Regular checks on the light setting and the headlight range on your own vehicle, manual headlight correction when the vehicle is loaded if necessary. Regular cleaning of the headlight covers and the vehicle windscreens, switching off the rear fog light and the high beam in good time, even with automatic/adaptive systems, if they do not turn off automatically as quickly as they should. All drivers should also regularly check their vision and glasses wearers should ensure that their glasses have an anti-glare coating and are kept clean.

Glare and traffic regulations

Drivers often claim that they drove through a red traffic light or missed a road sign, for example a speed limit sign, due to glare. However, this is generally not recognised by the courts as a mitigating circumstance, as drivers are obliged to adapt their driving style to the conditions, i.e. by reducing their driving speed in this case, and paying even more attention while driving.

Conclusion

Since glare poses a safety risk in road traffic, road users should increase their own awareness and train themselves in the issue. After all, if they know what they need to pay attention to or what precautions they can take to avoid glare, this will benefit all road users. Stricter regulations in the automotive industry, such as limiting luminance, could also help to improve the situation. Last but not least, innovative lighting solutions could also ensure greater safety on the road. Adaptive lighting systems, for example, could adapt the light distribution automatically to the relevant situation.

Advantages and disadvantages of all-season tyres

All-season tyres, often also known as all-weather tyres, are becoming increasingly popular. This is the conclusion drawn by the portal reifen.com. But what exactly are the differences and which tyre version is better suited to what type of people? The main differences are in the tyre profile and in the type of rubber used. All-season tyres can be driven all year round, provided they bear the Alpine symbol (3PMSF). This is prescribed for all-season tyres from year of production 2018. Only tyres with this snowflake symbol are actually approved for use as winter tyres. There is a transition period for M+S tyres produced until the end of 2017. These can still be used as winter tyres until 30.09. of this year.

What are the characteristics of a summer tyre?

Summer tyres are made of a slightly harder rubber and usually have a rougher profile, which means that they grip better in the rain, displace the water better and thus protect against aquaplaning. They also cope well with high temperatures and the rubber compound used guarantees safe driving on hot roads even at temperatures around 40 degrees Celsius. The braking power is good in both wet and dry conditions. It is important to know that the rubber compound of summer tyres hardens at temperatures below 7 degrees Celsius and thus loses its performance characteristics, especially on wet road surfaces. So you should never drive with summer tyres in winter.

And what about winter tyres?

The profile of winter tyres usually has many small fins and a larger tread depth. These ensure better grip in winter road conditions such as ice and snow, resulting in shorter braking distances. The rubber compound used is specially designed for cold temperatures, as it remains elastic even in frost and can thus adapt better to the surface structure of the road. Winter tyres are marked with the Alpine symbol (3PMSF mark).

All-season tyres - a compromise?

All-season tyres have a mixture of longitudinal grooves and fins and the rubber compound is a little softer and therefore more similar to the rubber compound of winter tyres. As a result, they combine the properties of summer and winter tyres. However, all-season tyres cannot match real winter tyres in extreme weather conditions. As with winter and summer tyres, a minimum tread depth of 1.6 millimetres is also required for all-season tyres, a minimum profile depth of 3 to 4 millimetres is recommended. It should also be noted that all-season tyres wear much faster, as they are driven all year round.

Conclusion

There is no clear recommendation. Ultimately, every driver has to decide which tyres are best suited for their requirements. For anyone who drives frequently in winter weather, perhaps even lives in the mountains and/or regularly go skiing, traditional winter tyres are the best option. All-season tyres can be a good compromise for anyone who prefers to leave the car at home in winter weather or only drives in the city and milder regions. After all, they combine the strengths of winter and summer tyres. Another advantage is that there is no need for the annoying tyre change and no storage space is required for the tyres that are currently not required. This saves time and money.

The new passenger car energy label

For many car dealerships and car dealers, it came very suddenly - the new passenger car energy label replacing the previous energy efficiency classes with the specification of a CO2 class. It came into force on 23 February without a transition period. Hardly feasible, as many car dealers note. The Central Association of the German Motor Vehicle Industry (ZDK) has also criticised this approach. If dealers fail to implement this change in time, they can expect warnings.

It came very suddenly, the new passenger car energy labelling regulation (Pkw-EnVKV). In concrete terms, this means: From 23 February 2024, all energy labels issued or published must meet the new requirements, there was no transition period. This was due to the Europe-wide switch to the WLTP test method (Worldwide harmonized Light vehicles Test Procedure).

So what's new?

In contrast to the previous energy label, which divided the vehicles into efficiency classes and only took consumption and emissions values into account, the new label divides the vehicles into CO2 classes and also contains additional information. This includes the amount of vehicle tax, the energy costs at a mileage of 15,000 kilometres per year and possible CO2 costs over the next ten years with an annual mileage of 15,000 kilometres.

One particular issue for dealers is that they have to state the expected CO2 costs over ten years. This involves a considerable amount of bureaucratic effort. They either have to request the data from the manufacturers or gather the details themselves in a different way. One saving grace is that labels created before 23/02/24 may still be used until 1 May this year. For advertising fonts and electronic, magnetic or visual storage media, the deadline is even 1 August this year.

What is the reason for the new passenger car energy label?

The new energy label is intended to provide consumers with better information regarding the energy efficiency of vehicle models. The vehicles are divided into seven CO2 efficiency classes, starting with the best energy efficiency class A, through to the worst class G. The aim is to reduce emissions from road traffic by encouraging consumers to buy cars with the lowest possible pollutant levels. There will be five energy labels in total, one for each type of fuel: Petrol, diesel, natural gas, pure electric vehicles and plug-in hybrids. The German government aims to improve acceptance with the introduction of the new energy label.

Glare in road traffic and why it poses a risk

Being dazzled when driving is not just unpleasant, but also dangerous. It is a common cause of accidents. A Europe-wide survey conducted by ADAC together with ten other automobile clubs, revealed that around 75 percent of drivers sometimes feel dazzled by bright lights from oncoming traffic.

How does glare affect drivers on the road?

Glare from the headlights and lights of other vehicles is not only a safety risk resulting in an increased risk of accidents, but also causes stress and discomfort for drivers. Many drivers feel impaired in the evenings in particular. Drivers complain that their visibility is restricted, especially in poor visibility conditions such as rain weather, snowfall or fog. The poorer visibility of objects is also listed as an issue. The survey also shows that it's not just older drivers who feel affected, but also many younger ones in the up to 35 age group. 21.8 percent of those surveyed even stated that they drive less in the dark overall.

What causes glare?

Drivers find it particularly disturbing when they are dazzled by the high beam of oncoming vehicles. However, the low beams are also regularly perceived as dazzling. The rear fog light is only perceived as disturbing by around a quarter of those surveyed. Daytime running lights, on the other hand, are not highlighted as having a major glare effect. However, the lighting on bicycles is increasingly being mentioned as a factor. This effect is also reinforced in the dark, and in specific ambient and weather conditions. Another factor is the increase in modern LED and laser light systems, as they can cause stronger glare.

What can drivers do to protect themselves against glare?

Most drivers react intuitively to glare. They often squint, look away briefly or, in the worst case, even close their eyes for a moment. This is a major problem for road safety. But what can drivers do to protect themselves and others from glare? The ADAC recommends the following measures: Regular checks on the light setting and the headlight range on your own vehicle, manual headlight correction when the vehicle is loaded if necessary. Regular cleaning of the headlight covers and the vehicle windscreens, switching off the rear fog light and the high beam in good time, even with automatic/adaptive systems, if they do not turn off automatically as quickly as they should. All drivers should also regularly check their vision and glasses wearers should ensure that their glasses have an anti-glare coating and are kept clean.

Glare and traffic regulations

Drivers often claim that they drove through a red traffic light or missed a road sign, for example a speed limit sign, due to glare. However, this is generally not recognised by the courts as a mitigating circumstance, as drivers are obliged to adapt their driving style to the conditions, i.e. by reducing their driving speed in this case, and paying even more attention while driving.

Conclusion

Since glare poses a safety risk in road traffic, road users should increase their own awareness and train themselves in the issue. After all, if they know what they need to pay attention to or what precautions they can take to avoid glare, this will benefit all road users. Stricter regulations in the automotive industry, such as limiting luminance, could also help to improve the situation. Last but not least, innovative lighting solutions could also ensure greater safety on the road. Adaptive lighting systems, for example, could adapt the light distribution automatically to the relevant situation.

Please contact us

*Required fields

Herth+Buss Fahrzeugteile GmbH & Co. KG

Dieselstraße 2-4

63150 Heusenstamm

Germany

+49 (0)6104-608-0

info@herthundbuss.com